|

How a synchromesh works on a modern gearbox.

This article describes the mysterious

thing called the synchromesh, i'm sure many of you have heard of it and know

what it does but i'm guessing as i used to, understanding how they work is

not so easy. This example is using a 5th gear from an Toyota E-51

transmission from the Supercharged MR2.

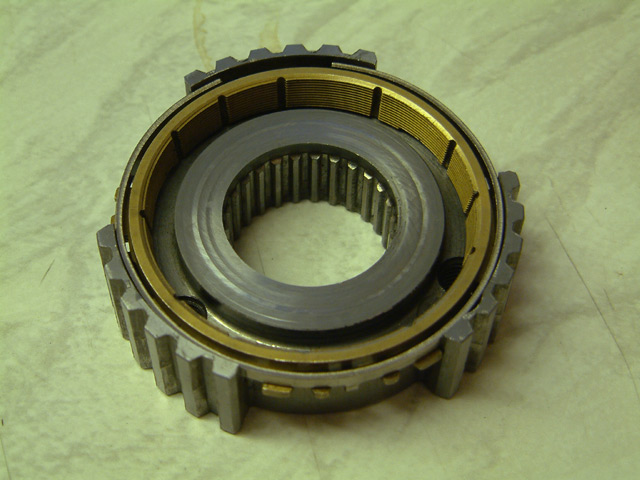

The 5 drive gear itself, this is normally located on the input shaft of the

gearbox, the 5th driven gear would be engaged on the larger outer cogs, the

drive gear is not locked to the input shaft in this box and idles on a set

of needle roller bearings. So if another gear is selected this will spin at

a different rate to the input shaft. The smaller teeth on the inner part engage

with the clutch sleeve when the gear is in use.

This shows the taper of the surface that mates with the inside of the

synchroniser ring.

This is the brass synchroniser ring itself, it's tapered on the inner side.

The synchroniser spring.

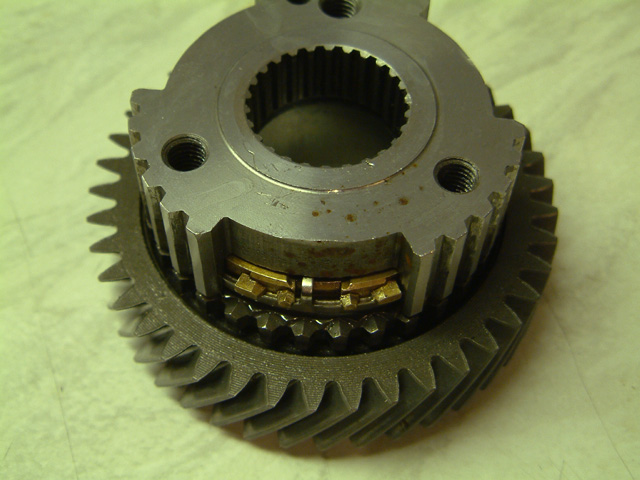

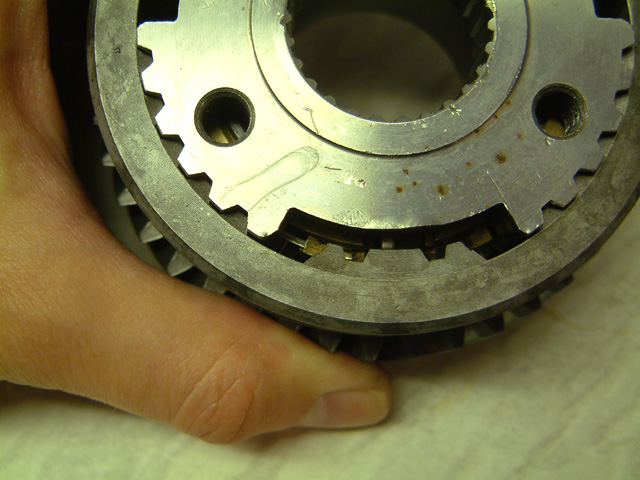

This is the 5th gear clutch hub, it is permanently attached to the input

shaft of the gearbox by the splines you can see in the inner side.

This is the clutch sleeve, it's this ring that actually engages the gear,

the inner teeth mesh with the smaller teeth that you can see on the 5th gear

and lock the clutch hub with the gear. There is a groove on the outer part,

the shift fork uses this to move the sleeve to engage or disengage the gear.

Here we have the synchroniser ring and spring installed into the clutch hub

Here we have the 5th gear with the synchroniser, spring and hub installed

together.

Lastly everything installed together

Ok, so how does all this stuff work? It's

actually quite simple. As we have a 5th gear here we'll use a 4th to 5th

gear shift. To engage the gear the teeth on the gear and the clutch hub need

to be spinning at the same speed and for the teeth to be in sync for the

sleeve to slip over and lock everything together.

When your in 4th the 5th gear will be

spinning at a different rate to the input shaft and the clutch hub, when you

go to change gear you disconnect the engine from the gearbox by using the

clutch and shifting into neutral, this means the input shaft is completely

free moving. What has to happen now is the speed of he input shaft must

match the speed of the 5th gear. The 5th gear is connected to the output

shaft by the 5th driven gear so if the car is in motion it will all be

spinning. When you go to shift the shift fork will push the sleeve towards

5th gear, this pushes against the synchroniser ring, because the

synchroniser ring and it's mating surface on the 5th gear itself are tapered

the synchroniser ring will grip the gear this will in turn speed up or slow

down the input shaft to the same speed as the 5th gear. Because the tips of

the cogs on the 5th gear, synchroniser ring and the sleeve are shaped like a

V they slip past each other, this aligns the sleeve with the gear and the

sleeve will lock over the 5th gear.

The following video clips demonstrate

this:

Clip 1

shows the gear locking together with the teeth of the sleeve and gear

aligned.

Clip 2 same as clip 1 but with the

teeth mis-aligned.

|